|

|

||||||||||||||||||||||||||||||||||||||

|

Drag reduction using compliant coatings The problem of drag reduction of the bodies moving in the fluid is significant and is one of the most important for the practical applications in aerohydrodynamics. An idea of using compliant coatings to reduce drag has been borrowed from the dolphins. It was assumed that special skin structure of dolphins essentially reduces their drag, and they reach very high speeds in the water. The use of compliant coatings is considered to be perspective in passive (i.e., without power supply) reduction of turbulent fluctuations and skin friction, as well as in laminar-turbulent transition delay.

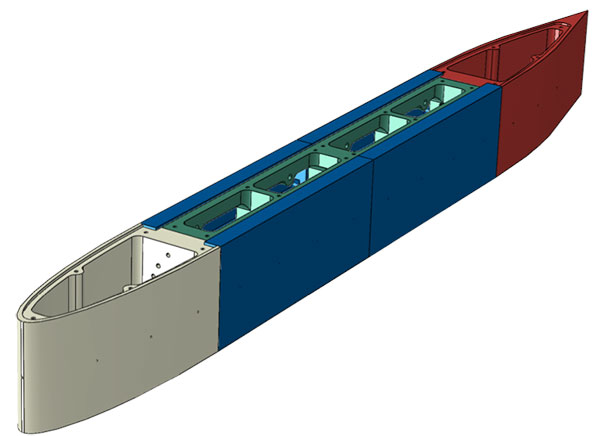

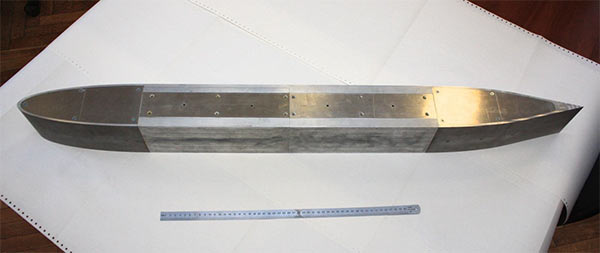

Test model with replaceable plates.

Three-dimensional scheme of the test model.

In numerous experiments, coating properties have not been measured and fixed by investigators, that is why many successful results are not confirmed by tests in other laboratories. At the present time, first, rigorous methods for measurements of viscous and elastic characteristics of compliant coatings are developed. Second, there are developed theories to describe interaction of visco-elastic material and fluid flow over it. These facts raise the investigations in this field to a much higher level. In collaboration with A.V. Boiko and V.M. Kulik (Russian Academy of Sciences, Novosibirsk) the study of drag reduction in water using compliant coatings is conducted in the laboratory of experimental hydrodynamics. Special test model has been designed. It has replaceable test plates (metal or compliant) at each side. The experiments are conducted in the water tunnel.

Photography of the assembled and disassembled test model.

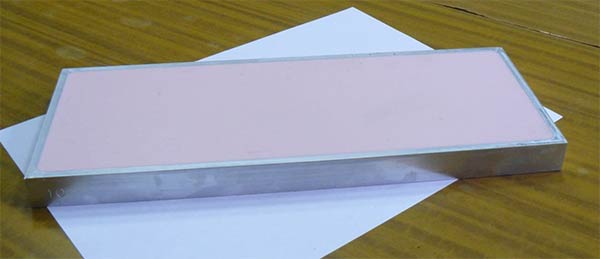

Replaceable plate with compliant coating.

The work has two lines of research. The first is devoted to the interaction of the compliant coatings with fully developed turbulent boundary layer. The goal is to detect the coating parameters most appropriate for drag reduction. Total drag force of the model and the local value of friction at the point (which is calculated from the averaged longitudinal velocity profile in the boundary layer) are measured. The measurements of the averaged velocity and its fluctuations are conducted using laser Doppler velocimeter.

Measurements of profiles of averaged velocity and its fluctuations in the turbulent boundary layer using laser Doppler velocimeter.

The second line of investigations is related to the influence of the compliant coatings to the stability of the laminar boundary layer (transition to the turbulence). Velocity and fluctuations profiles near the wall are measured, which give the location of the transition region and integral characteristics of the transitional boundary layer.

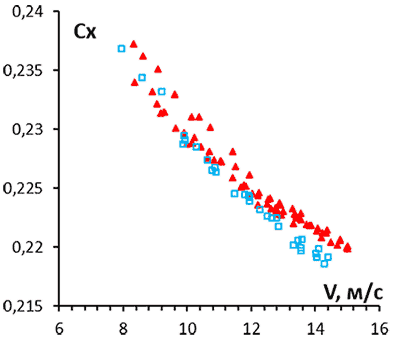

Total drag coefficient of the model Cx vs flow velocity for metal plates (squares) and compliant coatings of 4 mm in thickness (triangles).

|

||||||||||||||||||||||||||||||||||||||

| Last update: june of 2025 | |||||||||||||||||||||||||||||||||||||||